RMR is Leader of Machinery in the Baltic

RMR Ltd. will help you solve any problem – to develop a new component of your product or to change the entire product as a whole.

RMR is a modern company that follows innovations in quality control and production processes. All works are performed in accordance with ISO 9001.

Our employees work as a single team capable of realizing any of your ideas, regardless of the complexity of the tasks.

The company continues to grow through investment in the most advanced and state-of-the art technology.

RMR Ltd. can offer a client a full production cycle – from design development to a finished product – as it is a basic idea of our approach.

RMR Ltd. is a modern manufacturing company, offering advanced processing technology and high-quality management standards.

Today we can provide our Clients with a full range of services, from material processing to the manufacture of metal products of any complexity. Convenient geographical location allows us to send manufactured products to any country of the European Union and CIS countries.

The office and production facilities of the company are located in Latvia (Daugavpils region). The company is successfully and dynamically developing, carrying out its activities not only in the Baltic States, but also far beyond their borders.

RMR Ltd. will help you solve any problem – to develop a new component of your product or to change the entire product as a whole.

Efficiency. Quality. Professionalism. On-time delivery

Since its founding RMR Ltd has earned a reputation of uncompromising quality, outstanding service, loyalty to its customers, and competitive pricing.

Railway spare parts for locomotives.

Sleev

62B.85.04.000СБ

Sleev

62B.85.07.000СБ

Sleev

62B.85.03.000СБ

Cylinder head

5Д49.78.1СПЧ

5Д49.78СПЧ

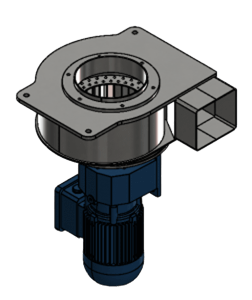

1st stage ventilator motor

62B.85.25.000СБ

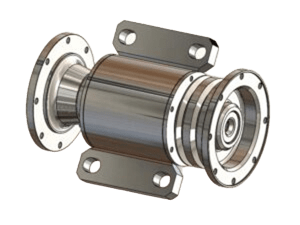

Intermediate support

TM34.030.000СБ

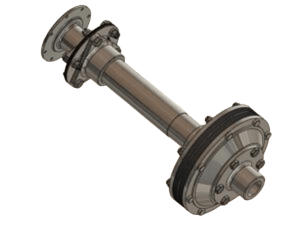

Line shaft

TM34.020.000СБ

Line shaft

TM54.010.00.000СБ

Shaft of the hidraulic reducer

62B.85.06.000СБ

Half-sleev

62В.85.05.000СБ

Shock-absorber

ТЭП60.01.01.012СБ

ТЭП60.01.01.021СБ

Collector

2TЭ10Л.10.30.94-98

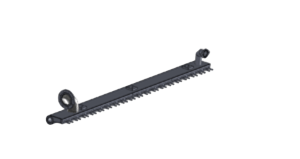

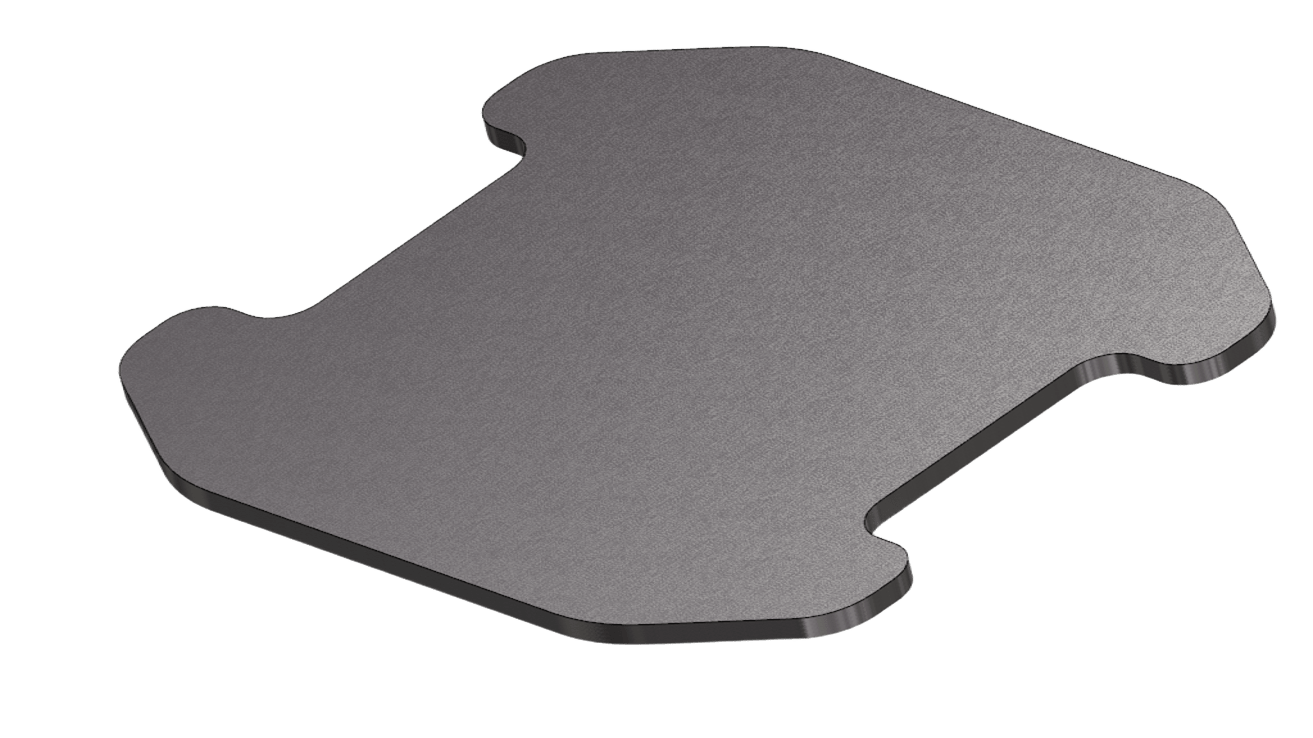

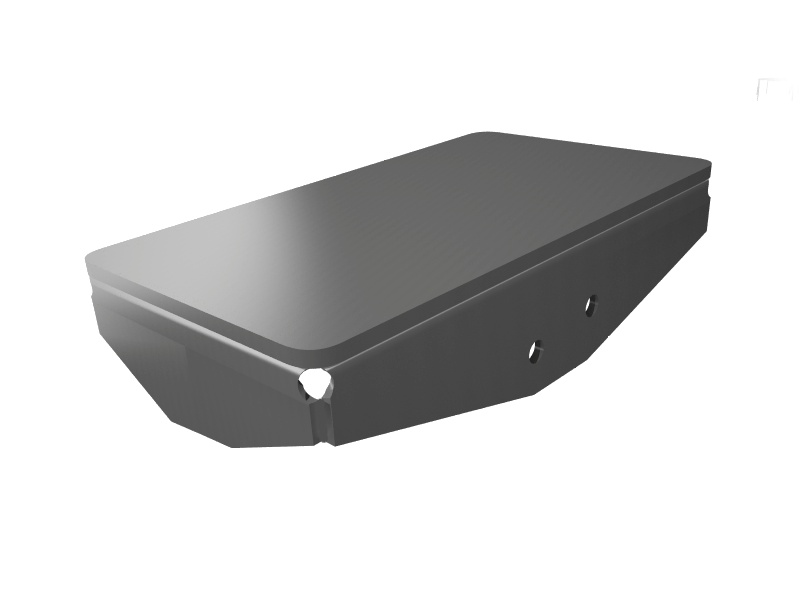

Railway spare parts for railcars.

Friction plate

М1698.02.001

Movable plate

М1698.02.004

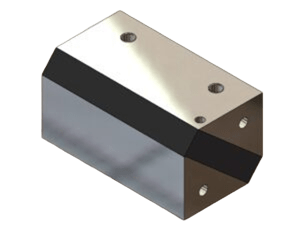

Spacer

М1698.01.005

Sliding cover

М1698.01.100СБ

Components for power transmission lines.

FULL – SERVICE

– Advices

– Technical task

– Delivery

– Start up Settings

– Warranty Service

– Service maintenance

We work only with reliable and sustainable partners. This allows us to offer the best solution to our customers!

WHY PARTNERS CHOOSE RMR

qualified employees

During its more than 20 years of development, RMR has accumulated a lot of knowledge and experience. The company seeks open and fair partnership. Our main asset is our highly-qualified personnel, which can work as a team or as individual specialists, and are professionals in their fields. The main priority of RMR is the timely provision of high-quality services according to international standards.

RMR was established in 2000 as a modern metalworking company that offers modern processing technologies with high quality management standards, follows the innovations in quality control and production processes.

Full production cycle from metal cutting to finished product:

- CNC machining

- CNC bending

- Different types of welding

- Machining

Over time, not only the total number of customers has increased, but also the needs of loyal customers, thus enabling us to develop and expand our business to meet new goals.

The company “RMR”Ltd. is actively working on the development of its dealer network in the Baltic States, Europe, Russia, Belarus.

directions of the enterprise

welding works

MIG-/MAG; TIG; MMA

Our welding work includes:

- Welding of different scope and complexity

- Advice on welding technology issues

- Specifications of welding procedures and technology schemes

- Development of new technologies of welding and thermal processing

- Supervision and coordination of welding work

- Examination of professional training for a welder

Welding methods:

- MMA – Manual Metal Arc welding with coated electrodes (111).

- TIG – Tungsten Inert Gas welding (141).

- MIG/MAG – Metal Inert Gas / Metal Active Gas welding (136/138).

MECHANICAL TREATMENT

Traditional machining of metal parts on machines applying following operations:

Drilling

- Turning

- Milling

- Round and flat grinding

- Boring on vertical and horizontal coordinate-boring machine

- Cold stamping by hydraulic press 160 t

- Tube bending on tube bending machines

- Sheet and profile material rolling

- Punching on crank press

- Bar cutting by guillotine (thickness up to 6 mm, length up to 2000 mm)

- Materials cutting on the band saws

- Finishing

design-engineering department

ANY TYPE OF ENGINEERING DOKUMENTATION:

DIAGRAMS, DRAWINGS, SPECIFIKATIONS, OPERATIONAL DOCUMENTS, explanatory notes,test programs, the company’s specialists will prepare quickly, efficiently AND ON TIME! The prices will pleasantly surprise you!

Our team can provide a complete design service; with most projects entailing some aspect of design, it helps to speak to our consulting engineer to ensure any design is spot on. We have a wide knowledge of materials and how they are to be put together, to ensure the highest standards.

QUALITY wARRANTY

ERP (Enterprice Resource planning system) has been introduced within the company, combining all manufacturing management and supervision processes.

our company holds the international quality control standard ISO 9001:2015

Visual testing Test method: LVS EN ISO 17637: 2017 – Non-destructive testing of welds – Visual testing of fusion-welded joints (ISO 17637:2016) EN ISO 9712-2016

incoming inspection / Non-destructive testing

Visual testing (VT)

Dye penetrant testing (PT)

Magnetic particle testing (MT)

Ultrasonic nondestructive testing (UT)

WE’ LL FIND THE BEST SOLUTION FOR YOU

—

Send us Your application and we will find a solution that is ideal for you.

CONTACTS

PHONE: +37120103368

E-MAIL: office@rmr.lv

ADRESS: Kalkūnes STREET 19H, Kalkūni, AUGšDAUGAVAS REGION, LATVIA, LV-5449

SIA “RMR” has signed Agreement No. 17.2-5-L-2024/198 with the Investment and Development Agency of Latvia (LIAA) for support under the Latvian Recovery and Resilience Mechanism Plan, Component 2 “Digital Transformation and Innovation”, financed by the European Union Recovery Fund.

Supported activity: Improvement of production and quality control processes.

Project’s digital transformation solution: Installation of two new CNC (Computer Numerical Control) machines equipped with computerized control software, enabling automation of the company’s core operations and full digitalization of the mechanical processing workflow.