RMR is Leader of Machinery in the Baltic

RMR is a modern company that follows innovations in quality control and production processes. All works are performed in accordance with ISO 9001.

Efficiency. Quality. Professionalism.

Since its founding RMR Ltd has earned a reputation of uncompromising quality, outstanding service, loyalty to its customers, and competitive pricing.

OUR PRODUCTION

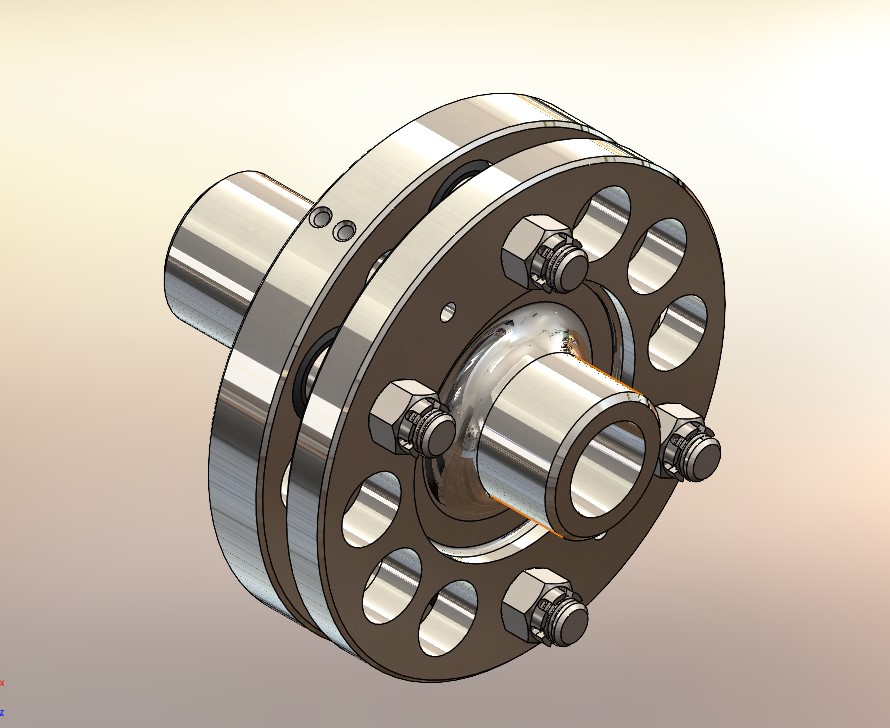

SLEEV

62B.85.04.000СБ

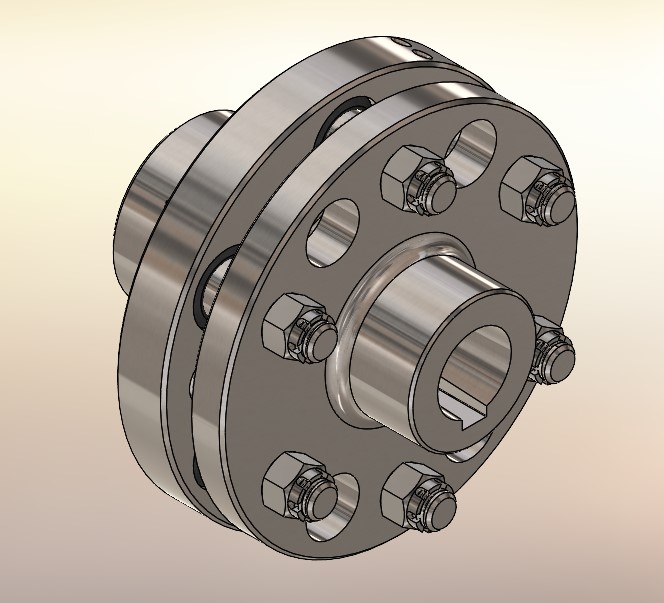

SLEEV

62B.85.07.000СБ

SLEEV

62B.85.03.000СБ

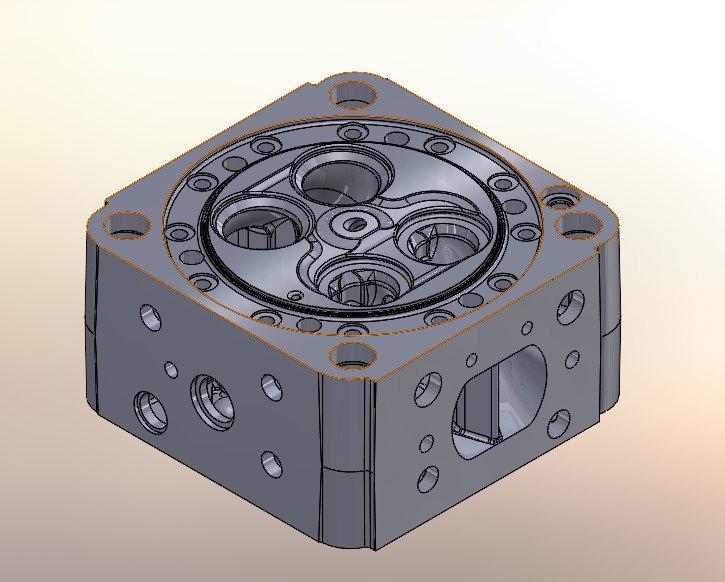

CYLINDER COVER

5Д49.78.1СПЧ

5Д49.78спч

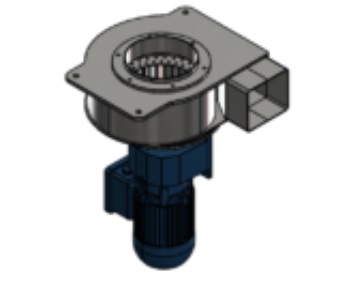

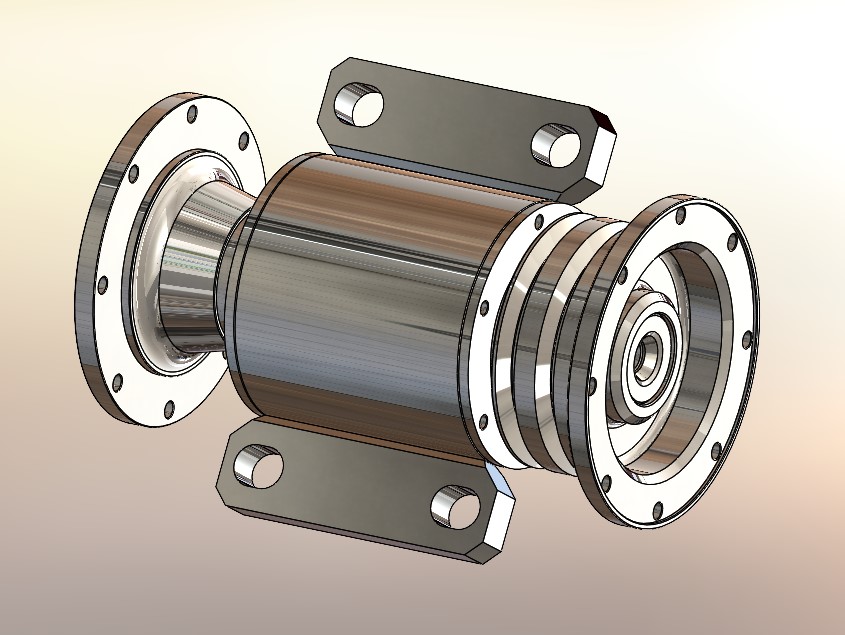

1ST STAGE VENTILATOR MOTOR

62b.85.25.000СБ

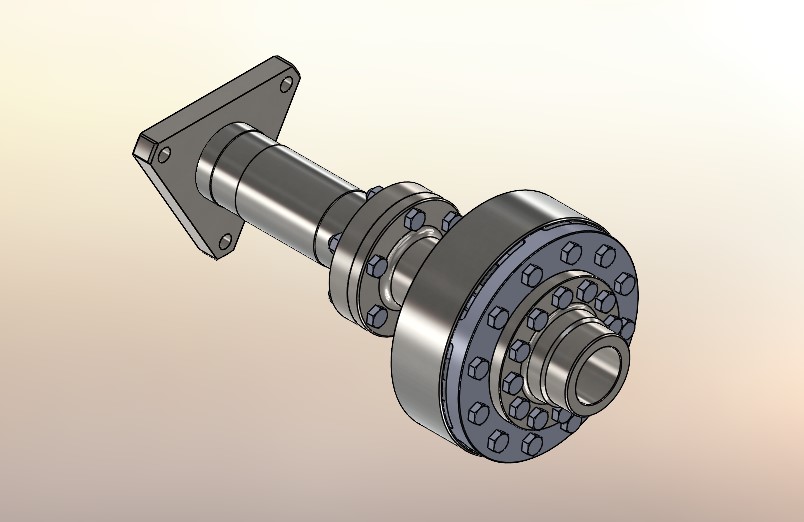

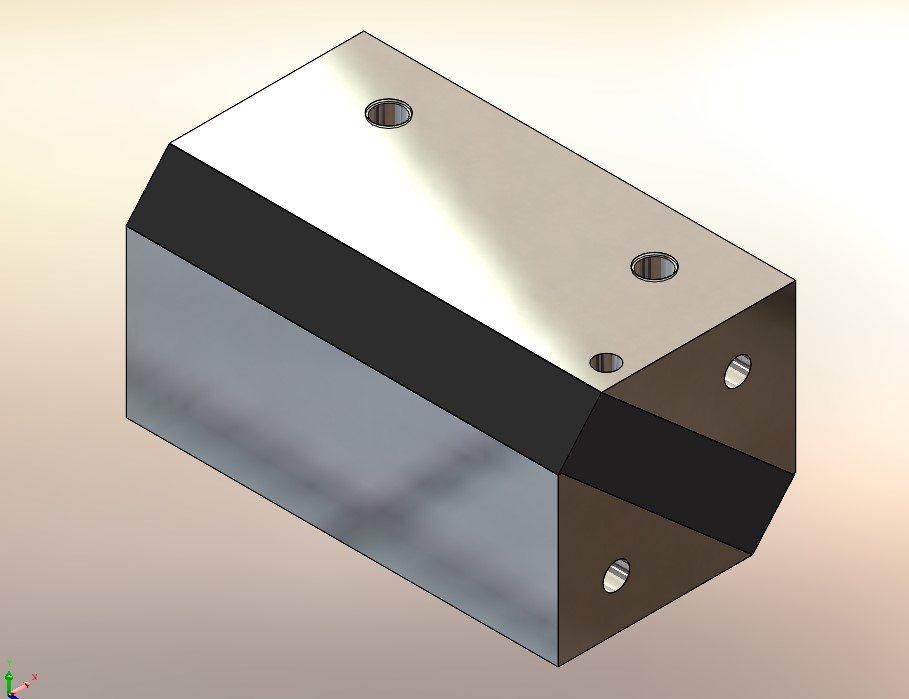

intermediate support

TM34.030.000СБ

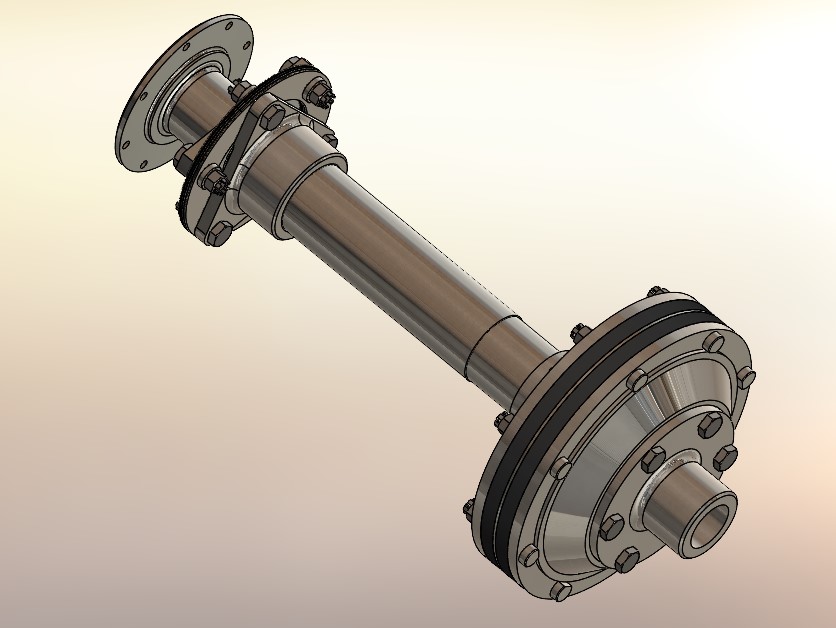

LINE SHAFT

TM34.020.000СБ

LINE SHAFT

TM53.010.00.000СБ

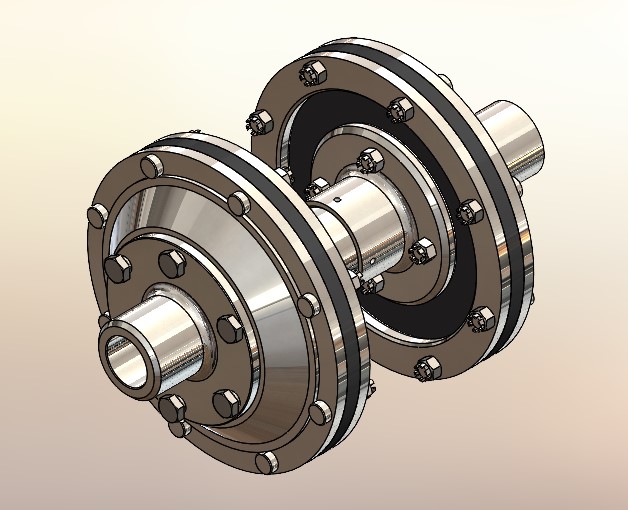

SHAFT OF THE HIDRAULIC REDUCER

62B.85.06.000СБ

HALF-SLEEV

62В.85.05.000СБ

shock-absorber

ТЭП60.01.01.012СБ

ТЭП60.01.01.021СБ

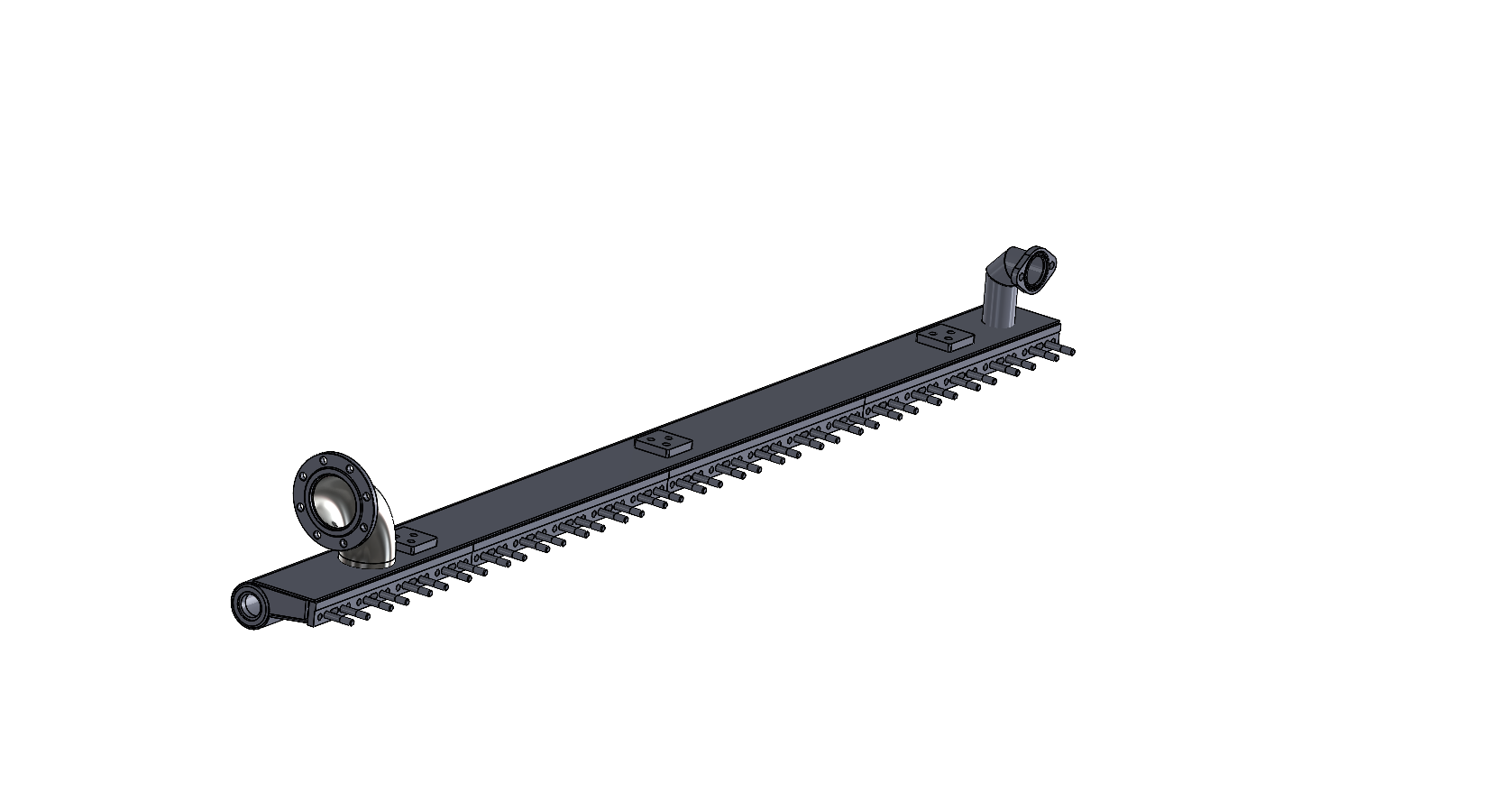

COLLECTOR

2TЭ10Л.10.30.94-98

FULL – SERVICE

– Advices

– Technical task

– Delivery

– Start up Settings

– Warranty Service

– Service maintenance

We work only with reliable and sustainable partners. This allows us to offer the best solution to our customers!

WHY PARTNERS CHOOSE RMR

qualified employees

During its more than 20 years of development, RMR has accumulated a lot of knowledge and experience. The company seeks open and fair partnership. Our main asset is our highly-qualified personnel, which can work as a team or as individual specialists, and are professionals in their fields. The main priority of RMR is the timely provision of high-quality services according to international standards.

RMR was established in 2000 as a modern metalworking company that offers modern processing technologies with high quality management standards, follows the innovations in quality control and production processes.

Full production cycle from metal cutting to finished product:

- CNC machining

- CNC bending

- Different types of welding

- Machining

satisfied customers

Over time, not only the total number of customers has increased, but also the needs of loyal customers, thus enabling us to develop and expand our business to meet new goals.

The company “RMR”Ltd. is actively working on the development of its dealer network in the Baltic States, Europe, Russia, Belarus.

directions of the enterprise

welding works

MIG-/MAG; TIG; MMA

Our welding work includes:

- Welding of different scope and complexity

- Advice on welding technology issues

- Specifications of welding procedures and technology schemes

- Development of new technologies of welding and thermal processing

- Supervision and coordination of welding work

- Examination of professional training for a welder

Welding methods:

- MMA – Manual Metal Arc welding with coated electrodes (111).

- TIG – Tungsten Inert Gas welding (141).

- MIG/MAG – Metal Inert Gas / Metal Active Gas welding (136/138).

We weld the following types of steel:

- Non-alloy and low-alloy

- Stainless

- Duplex

All our welding work is carried out in accordance with strict international standards. Our welders are certified according to the EN ISO 9606-1:2013 and PED97/23/EC standards.

MECHANICAL TREATMENT

Traditional machining of metal parts on machines applying following operations:

- Drilling

- Turning

- Milling

- Round and flat grinding

- Boring on vertical and horizontal coordinate-boring machine

- Cold stamping by hydraulic press 160 t

- Tube bending on tube bending machines

- Sheet and profile material rolling

- Punching on crank press

- Bar cutting by guillotine (thickness up to 6 mm, length up to 2000 mm)

- Materials cutting on the band saws

- Finishing

design-engineering department

ANY TYPE OF ENGINEERING DOKUMENTATION:DIAGRAMS, DRAWINGS, SPECIFIKATIONS, OPERATIONAL DOCUMENTS, explanatory notes,test programs, the company’s specialists will prepare quickly, efficiently AND ON TIME! The prices will pleasantly surprise you!

QUALITY wARRANTY

Service and quality have become the new mandate while continuing to provide cost effective products.

ERP (Enterprice Resource planning system) has been introduced within the company, combining all manufacturing management and supervision processes. This system ensures the complete traceability of raw materials and manufacturing processes.

Our quality policy aims for zero defects in our products, timely services, and excellence in product and service.

RMR Ltd. company holds the international quality control standard ISO 9001:2015

EN ISO 9712-2016

incoming inspection / Non-destructive testing

Visual testing (VT) is based on obtaining information about the tested material with the help of visual observation or of optical and measuring instruments. Visual testing method allows detecting discontinuities, deviations of the size and shape from the specified ones for more than 0.1 mm when using instruments with magnification up to 10x.

Visual testing Test method: LVS EN ISO 17637: 2017 – Non-destructive testing of welds – Visual testing of fusion-welded joints (ISO 17637:2016)

Visual inspection (VT) is arguably the oldest and most widely used NDT method there is. This method involves the visual observation of the surface of a test object to evaluate the presence of surface discontinuities such as corrosion, misalignment of parts, physical damage and cracks. Visual testing can be done by looking at the test piece directly, or by using optical instruments such as magnifying glasses, mirrors, borescopes and computer-assisted viewing systems. VT can be applied to inspect castings, forgings, machined components and welds and is used in all branches of industry.

Dye penetrant testing (PT) method is based on penetration of liquid penetrant into open surface discontinuities. PT is not applicable on high porous materials.

Dye penetrant method is applicable for surface defects determination: surface cracks, pores, lack of fusion, inter-granular corrosion, etc.

Dye penetrant testing is performed on welds and parent material of all potentially dangerous installations.

Testing standards: LST EN ISO 3452-1:2013, PNAE G-7-018-89, GOST 18442-80.

Certified personnel: 41 PT level 2 specialists certified according to LST EN ISO 9712.

Magnetic particle testing (MT) method is performed on welds and parent material of all potentially dangerous installations and is applicable for surface and subsurface defect detection. MT is used on ferromagnetic materials only.

Ultrasonic nondestructive testing (UT), also known as ultrasonic NDT or simply UT, is a method of characterizing the thickness or internal structure of a test piece through the use of high frequency sound waves. The frequencies, or pitch, used for ultrasonic testing are many times higher than the limit of human hearing, most commonly in the range from 500 KHz to 20 MHz.

WE’ LL FIND THE BEST SOLUTION FOR YOU

—

Send us Your application and we will find a solution that is ideal for you.

CONTACTS

+371 20103368

![]() E-MAIL:

E-MAIL:

![]() ADRESS:

ADRESS:

Kalkūnes STREET 19H, Kalkūni, AUGšDAUGAVAS REGION, LATVIA, LV-5449